I have quickly grown to love the Bambu Lab H2S. I have been reviewing 3D printers for some time now, and I am genuinely impressed by how far the technology has advanced, even in just the past few years. At the forefront of that progress is Bambu Lab, whose printer lineup delivers impressive print quality alongside some of the most user-friendly tools available in the industry.

With the H2S, Bambu Lab introduces a large, single-nozzle successor to its flagship H2D, aimed at makers who want speed, reliability and significantly more room to work, without the complexity of an advanced multi-toolhead system. The printer retains the familiar H-series design language and ecosystem, but shifts the focus back to straightforward FDM printing in a very large enclosed machine that still fits neatly within Bambu Lab’s broader lineup.

Unboxing the H2S is very much a two-person job. This is a substantial printer, and its size alone makes that immediately clear. Before any printing can begin, however, setup is required. Out of the box, the H2S arrives fully assembled and securely packaged. Combo versions ship with the optional AMS 2 Pro mounted inside the frame for transport, while standalone AMS units arrive separately for those who purchased them individually.

Setup primarily involves removing protective foam, tape and shipping screws, mounting the AMS on top if applicable, connecting a data cable and PTFE tube, and then running a guided initialization process. That process includes extensive self-checks, vibration compensation and automatic bed levelling, and can take more than 30 minutes on the first run.

Once calibration is complete, filament loading through the AMS is largely hands-off. Users feed a short length of filament into the feeder, and the system takes over, routing it to the toolhead and registering the spool automatically. For flexible materials such as TPU, the AMS can be bypassed in favour of a rear feed port and an external dry box if needed.

Maintenance routines are also built directly into both the printer’s screen and companion apps, with reminders for lubrication, cleaning and parts replacement. This approach is clearly designed to help long-running print farms stay on top of upkeep without relying on external tracking tools. Bambu Lab has made getting the H2S up and running remarkably easy, removing much of the guesswork that made older machines tedious to set up. The app experience, in particular, feels intuitive and polished, addressing an area where many previous-generation printers fell short.

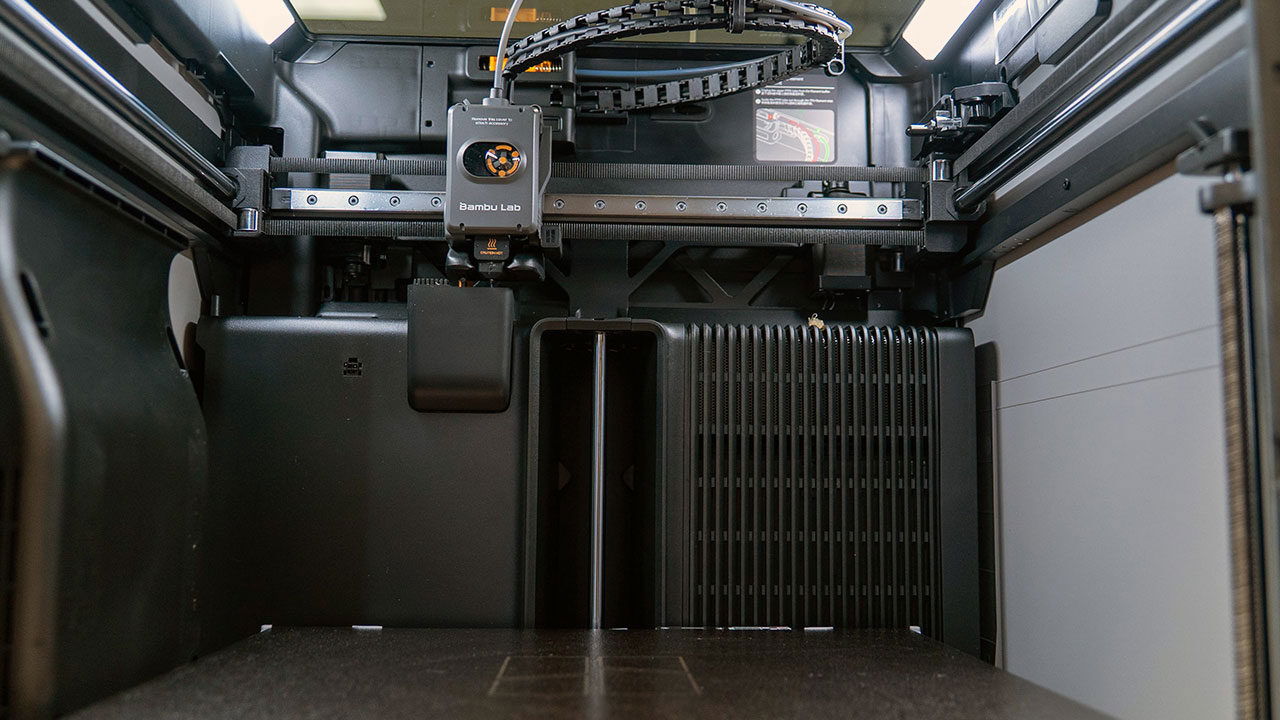

Once everything is set up and the printer is ready to produce its first 3D model, the fun truly begins. From a specifications standpoint, the Bambu Lab H2S is a fully enclosed CoreXY printer, similar to the Prusa Core One, built around a steel chassis with plastic and glass panels. It shares nearly the same footprint as the dual-nozzle H2D. Inside, the standout specification is the 340-by-320-by-340-millimetre build volume, which makes full use of the build plate thanks to the single-nozzle design.

The enclosure supports a hardened steel hot end rated up to 350 °C, a heated bed capable of reaching 120 °C, and an actively heated chamber that reaches approximately 65 °C. This makes the H2S well-suited for materials such as ABS, ASA and nylon, and it prints them all fantastically, although more on that in a bit.

Bambu Lab continues to use its quick-swap nozzle system, which relies on a clasped, magnet-held assembly that can be removed without tools once the silicone cover is taken off. A standard 0.4-millimetre nozzle comes preinstalled, but the printer supports a range of other sizes, including a higher-flow option rated at up to 65 cubic millimetres per second when paired with appropriate print profiles. Surrounding the toolhead is a dense cooling and filtration system that includes multiple fans, automatic vents and a combined HEPA and carbon filter. This setup allows the printer to transition between tightly sealed, high-temperature prints and cooler PLA jobs without requiring the door to be opened.

Like other Bambu machines, the H2S leans heavily on automation and monitoring. It features an updated motion system driven by a permanent magnet synchronous motor, which increases extrusion force while enabling speeds of up to a claimed 1,000 millimetres per second and acceleration of 20,000 millimetres per second squared. In real-world use, however, performance gains tend to translate to roughly a 20 to 30 per cent reduction in print times compared with typical fast CoreXY profiles.

Inside the enclosure are 23 sensors monitoring everything from filament flow to chamber conditions, supported by three cameras. One is used for live viewing, another focuses on the nozzle for fault detection, and a third handles general monitoring and calibration. For anyone coming from an entry-level printer, such as a Creality Ender 3, the H2S exists in an entirely different class. It is designed to deliver consistent, high-quality prints with minimal effort, removing much of the guesswork from the process.

The printer ships with a five-inch touchscreen that mirrors the more polished, visual interface Bambu has been rolling out in Bambu Studio, its slicing and control software for Windows, macOS and Linux. Remote control and camera access are handled through the desktop application and the mobile Bambu Handy app. The H2S also supports USB and local network printing for users who prefer not to rely on cloud connectivity.

Bambu Lab has clearly streamlined the overall experience, smoothing out many of the pain points that plagued older software and firmware. The result is a workflow that feels closer to the refined user experience found in other consumer technology sectors than the more utilitarian, Marlin-based systems many long-time 3D printing enthusiasts are accustomed to.

“All of these features would mean little if the printer failed to deliver solid 3D prints, and thankfully, the Bambu Lab H2S does not disappoint.”

On the materials side, the H2S works with the AMS 2 Pro, which doubles as a filament dryer and can chain multiple units together to support 16 or more loaded spools. The AMS 2 Pro uses integrated heating, ventilation, desiccant and automatic spool rotation during drying. It can also read RFID tags on Bambu-branded filament to automatically set material type and colour. Older AMS units remain compatible, allowing existing Bambu Lab users to migrate their hardware rather than start from scratch.

All of these features would mean little if the printer failed to deliver solid 3D prints, and thankfully, the Bambu Lab H2S does not disappoint. In testing, the H2S leans into its single-nozzle identity, prioritizing consistent, high-speed single-material printing while still handling multi-colour jobs through the AMS when required. Benchmarks such as 3D Benchy and more demanding calibration models produced clean walls, minimal ringing and strong dimensional accuracy. Across standard tests conducted at CGMagazine, the aggregated XY error was measured at less than half a millimetre.

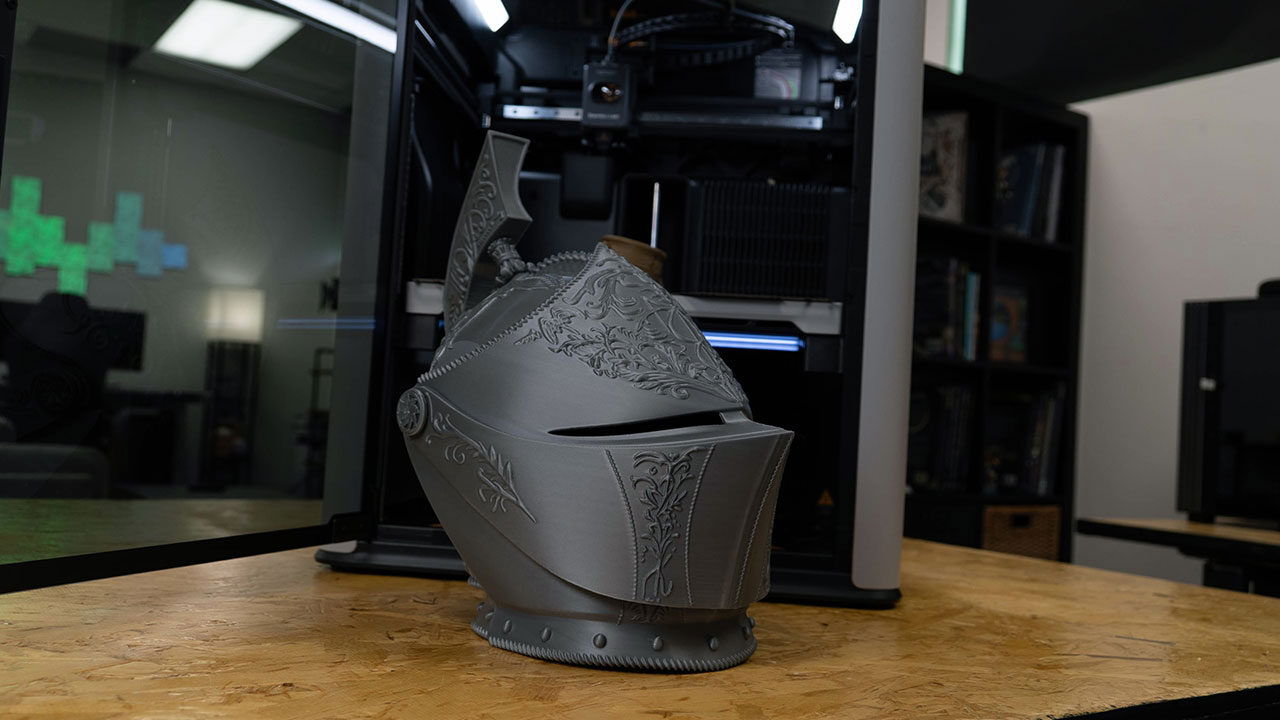

The high-temperature enclosure and hardened nozzle allow the printer to handle materials ranging from PLA and PETG to carbon-fibre nylon and engineering-grade blends. With tuned profiles, the machine produces stiff, matte parts with well-concealed layer lines. Large-format projects, including cosplay helmets and modular storage systems, benefit greatly from the expansive build volume. The build plate can accommodate either large single pieces or dense batches of smaller parts, helping to amortize print time and purge waste. During testing with PETG-CF, the printer consistently delivered detailed, precise results without issue. It also handled more demanding filament types with ease, even on larger and more complex models, which is a strong showing overall.

“Despite the lack of tool-changing support, the Bambu Lab H2S still delivers most of the features makers would expect from a modern, high-end 3D printer.”

That said, one notable drawback emerges when switching to multicolour printing. Each colour change requires purging through the rear chute, and long, multi-material prints can generate more waste material than finished output. Print times for the same multicolour designs also come in slower than on the dual-nozzle H2D, although the difference typically amounts to a few additional hours on day-long prints rather than a doubling of total print time.

For users who primarily print in single materials or only occasionally add accent colours, this trade-off is relatively easy to accept. Those who rely heavily on soluble supports or complex multi-material workflows may find the limitation harder to overlook. Ultimately, it depends on individual workflow needs and whether these constraints pose a problem for the kind of work planned on the printer.

With a base unit priced at about $1,249 USD and the AMS 2 Pro combo costing roughly $1,499 USD, the H2S undercuts the H2D while landing slightly above the retiring X1 Carbon with AMS. This positions it squarely as a mainstream option within the Bambu Lab lineup. It retains the brand’s plug-and-play reputation, full enclosure and AMS integration, but trades the H2D’s dual-nozzle efficiency for a simpler motion system and a slightly larger usable build area.

That said, it remains a more expensive option than entry-level competitors such as the Creality K2 Pro, priced at about $1,200 USD, which may matter to those just starting out in 3D printing. At the same time, it is more affordable than higher-end alternatives like the Prusa Core One L, which costs around $1,799 USD. Despite the lack of tool-changing support, the Bambu Lab H2S still delivers most of the features makers would expect from a modern, high-end 3D printer.

For creators, design studios and print farms that primarily run single-material parts and value speed, uptime and an enclosed, high-temperature workspace, the H2S fits neatly as a reliable workhorse that can still handle multicolour printing when needed. Hobbyists who print only occasionally and do not require the expansive build volume may find better value in smaller Bambu models or offerings from other brands. For users who have outgrown mid-sized build plates, or who want a single machine capable of producing helmets, armour and large functional parts, the H2S is clearly designed with that scale of work in mind.