If you follow the world of 3D printing, you may have heard of Prusa, a leader in the field known for producing some of the highest-rated 3D printers available today. While its products often come at a premium, they offer some of the easiest operation and most refined features on the market, helping users get started quickly without the fuss found with other brands. And now, Prusa has entered the CoreXY 3D printer market with its new Prusa Core One, and it feels like something special.

After testing it for a few weeks, it’s clear this model marks a decisive new chapter for the company. Following much anticipation from long-time enthusiasts, the Core One finally delivers the enclosed speed and versatility many have been waiting for, while maintaining the brand’s trademark accessibility and attention to detail. For tinkerers, educators and small workshop owners, the result is a printer that feels refreshingly practical without crossing into cold, industrial territory.

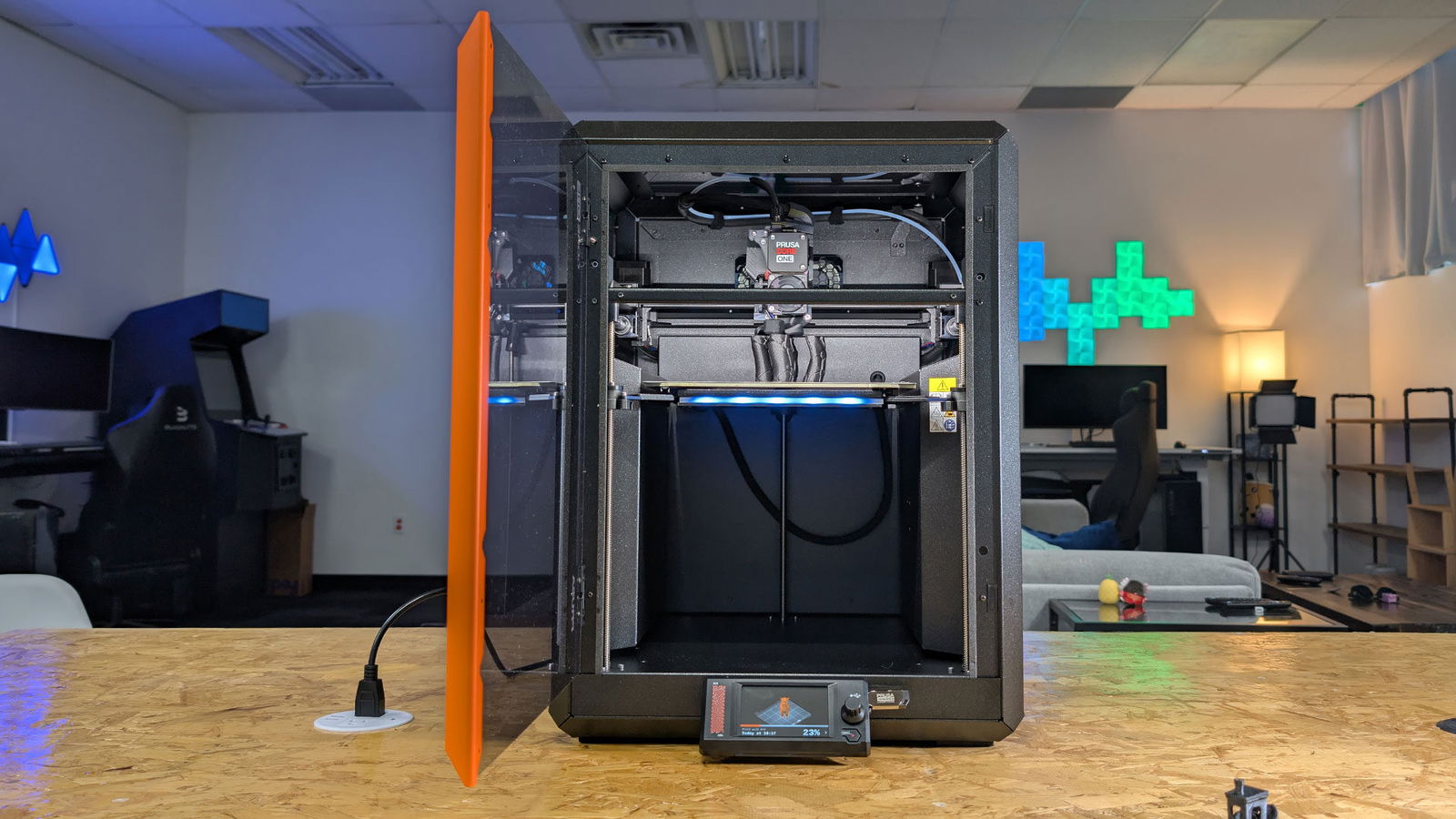

After unboxing and setting up the Prusa Core One in the office, I was struck by how sturdy and compact the machine feels. Rather than relying on glue or welds, every part of the frame can be dismantled with a screwdriver. This design not only makes maintenance easier for those less mechanically inclined but also builds confidence in anyone new to hands-on 3D printing.

Prusa’s design uses a rigid steel exoskeleton, creating an enclosure that is both durable and user-serviceable. The polycarbonate sides offer a clear view of ongoing prints, while thoughtful design tweaks help keep stray dust and static at bay. I’ve used a range of 3D printers over the years, and none have felt this well constructed while maintaining such a strong balance between fixability and upgradability.

It’s time to look at what makes this machine stand out from alternatives or other models Prusa has already released. The CoreXY architecture isn’t a throwaway marketing term—it plays a major role in transforming the printing experience compared with classic “bedslinger” designs such as the Prusa MK4S. CoreXY refers to how the print bed and print head move: the bed raises to meet the print head, while the head moves only along the X and Y axes. This setup makes printing faster and often—depending on the machine—more accurate.

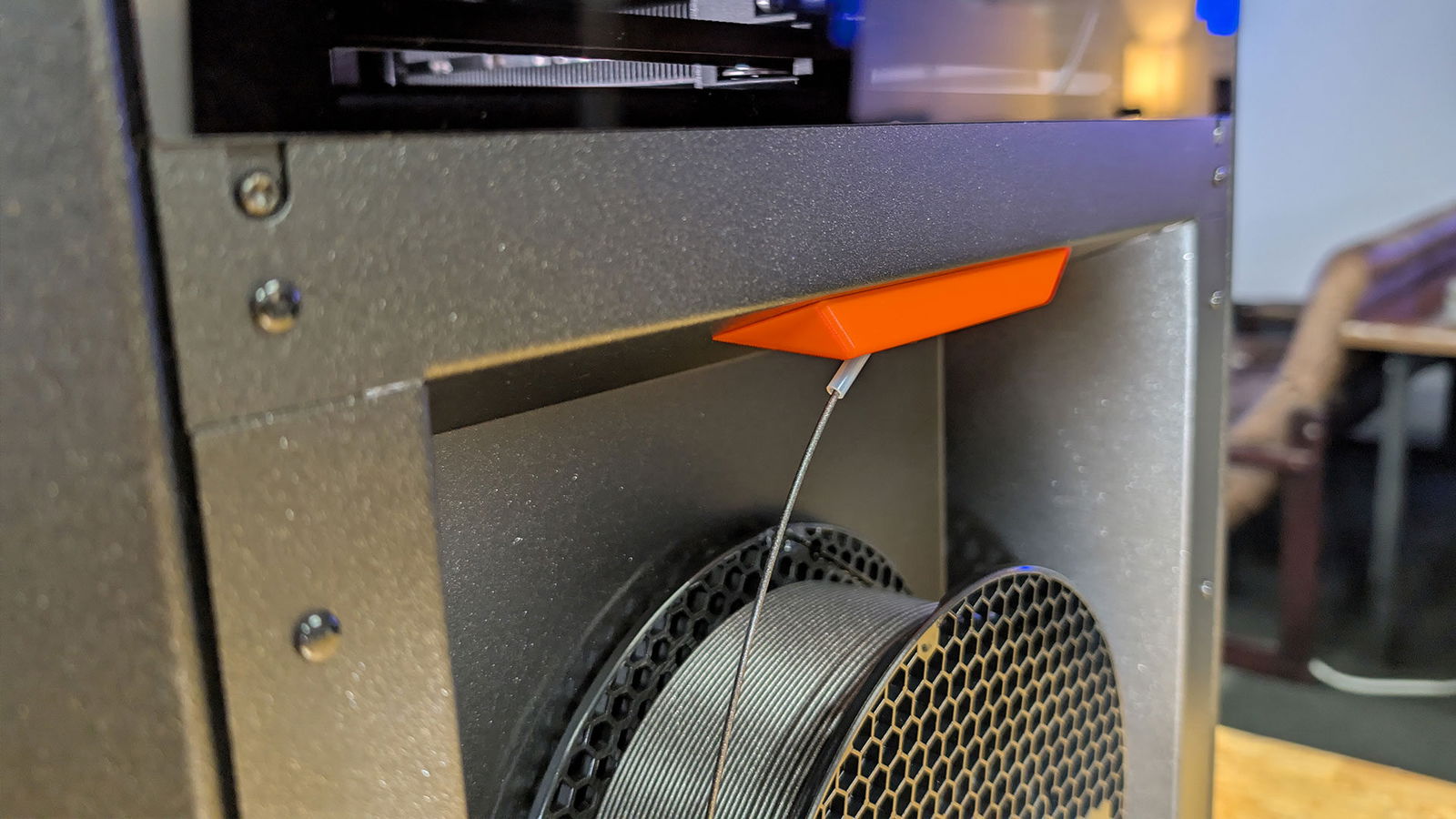

The build volume measures 250 by 210 by 270 millimetres, offering more vertical space than its predecessor while taking up noticeably less room on a desk or shelf. Anyone tight on space will appreciate this efficiency, especially with the integrated spool holder and the enclosure’s smart side indents. The build plate may not be as big as some printers on the market, but it is more than enough for a range of projects, and offers plenty of flexibility, although more on that later.

“I put the Prusa Core One through its paces with a range of filament types and projects, and the machine held its own even on more complex prints.”

Speed is one of the main advantages of the Prusa Core One, and the machine delivers. Prusa hasn’t leaned on arbitrary “maximum speeds” in its official specifications, but in practical tests, prints averaged 15 to 20 per cent faster than many standard bedslinger printers on the market—without sacrificing the crisp, tidy finish the company is known for.

This performance is thanks, in part, to a high-flow 0.4-millimetre CHT nozzle and refined motion tuning, particularly on travel moves and infill passes. The enclosure’s active air circulation keeps printing conditions stable, even when working with finicky materials such as ABS or ASA. It’s easy to preheat the chamber for technical filaments, and there’s no need to keep the door cracked open when using PLA—a welcome convenience for home or classroom use.

Returning to the setup process, Prusa has clearly focused on keeping things approachable. The printer ships either pre-assembled or as a kit, depending on the buyer’s preference. For those choosing the kit, setup is said to take less than a day, even for beginners, thanks to the company’s thorough documentation (though I haven’t tried this personally).

A charming cartoon start-up sequence greets users on the full-colour touchscreen. Bed levelling is handled automatically by a nozzle-mounted load cell, which gently taps the build surface and adjusts on the fly—making perfect first layers nearly guaranteed. Loading and changing filament is equally straightforward, guided by on-screen prompts that minimize guesswork during material swaps.

I have to say, Prusa has made the process of 3D printing almost painless, with the experience feeling intuitive and straightforward. Of course, there will always be minor issues along the way, but never has the workflow felt this refined and clear. It’s a hobby that’s truly coming into its own, and Prusa is clearly at the forefront of making that a reality.

Looking over at the software side of things, PrusaSlicer, while dense with options, comes preloaded with tuned profiles for a range of filament types and includes model files and resources directly on the USB drive. Networked users can take advantage of LAN or Wi-Fi connections, with a much-improved Prusa Connect app now supporting real-time print monitoring. While not strictly necessary, an optional Buddy Camera can be attached to the chamber for remote visuals. It’s an overall package that feels ready for prime time, offering everything you need to start printing and to ensure your results look solid every time.

While I only touched on it briefly, one major advantage of the CoreXY design—and of being fully enclosed—is that the Prusa Core One is ready for most filament types, including PLA, PETG, TPU, ABS, ASA and polycarbonate. It supports nozzle temperatures of up to 300 °C. The chamber temperature is regulated primarily by the heated bed, which is efficient but can take some time to ramp up for challenging materials, especially in cooler workshops.

During typical home or office use, however, the system maintains consistent print quality and minimizes the risk of warping or delamination. The thoughtful inclusion of a reversible door hinge and child-safety measures, such as an automatic alarm when the door is opened during a print, rounds out the printer’s strong safety profile.

I tested a range of prints and filament types and never encountered issues with warping or print quality. Aside from a few failed jobs caused by improperly loaded filament or a mid-print power outage, most results turned out perfectly. The few that did fail were due to minor slicer settings, not hardware. Overall, the Prusa Core One proved to be a rock-solid companion—something I can’t say for most models I’ve tested to date.

I was impressed by how quiet the Prusa Core One was in operation. While I wouldn’t recommend placing it in a bedroom or living space—printing with melted plastic always carries some risk—I barely noticed the sound when it was running in the front offices at CGMagazine. The stepper motors and motion system produce a slightly more distinct hum than previous Prusa models I have heard or tested at trade shows, but the built-in fans settle into a soft background tone that’s unlikely to disturb a typical workspace. The build plates remain easy to swap and clean, and many consumables are shared with the Prusa MK4S, making upgrades or transitions simple.

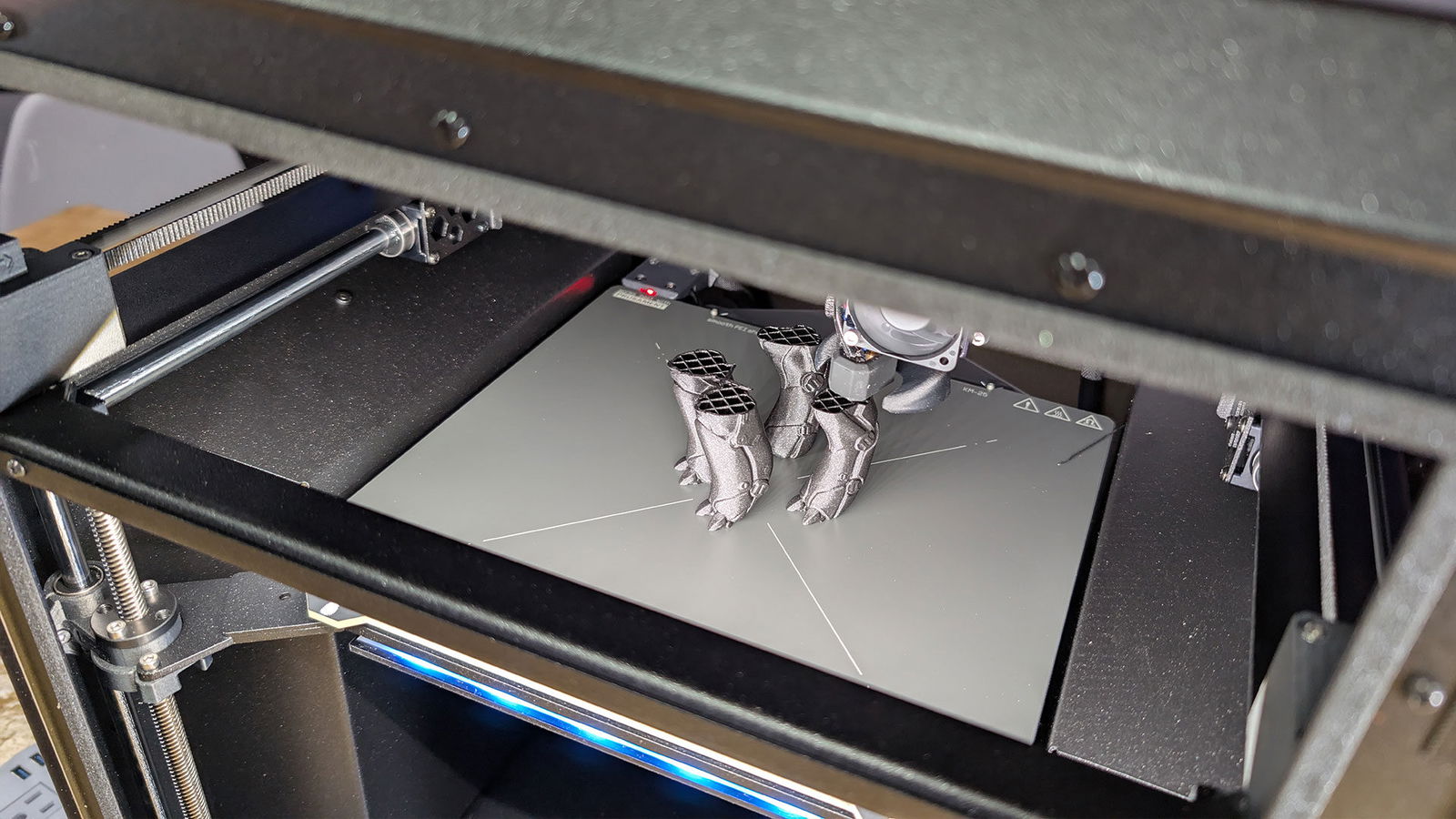

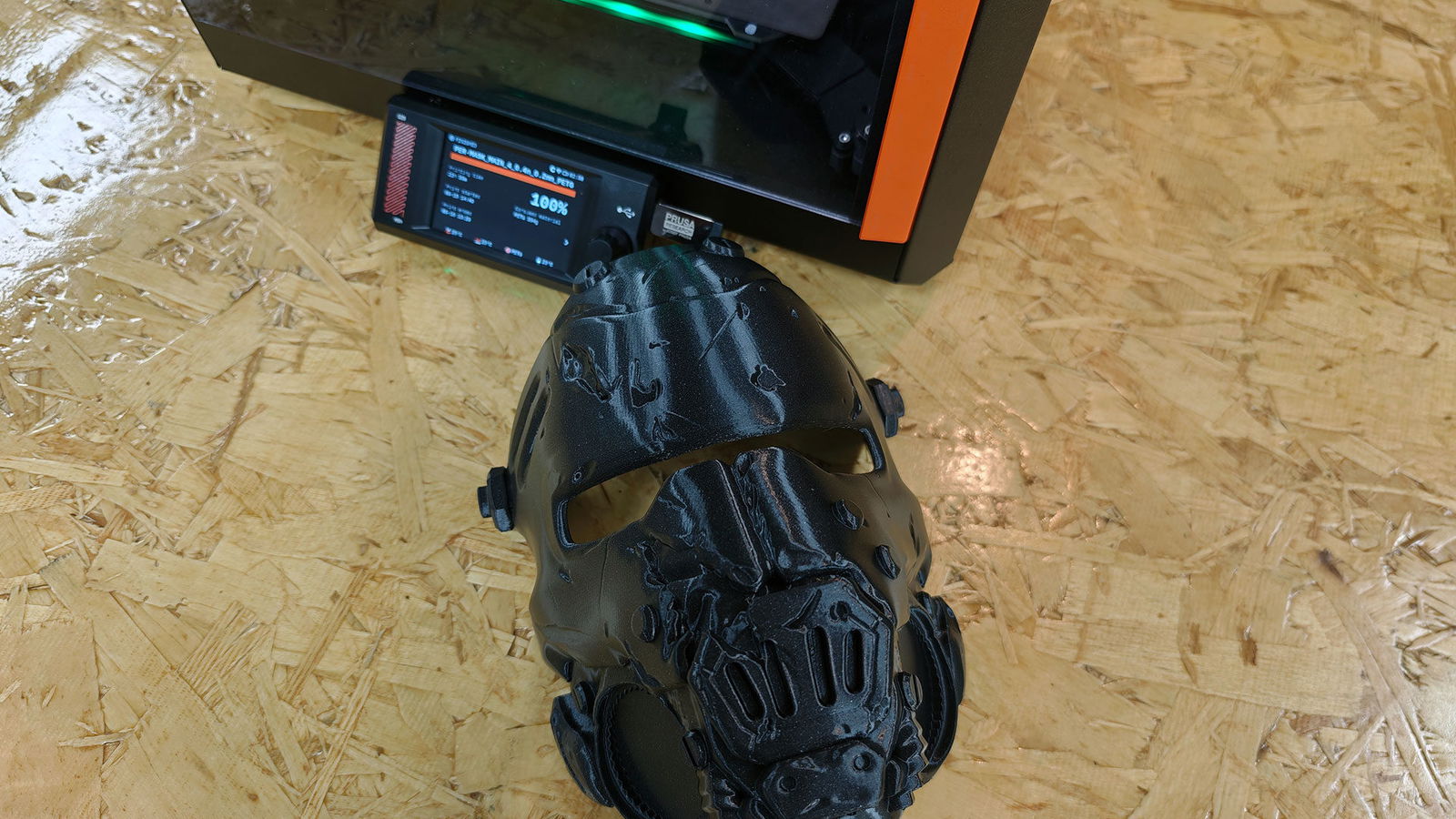

For testing, I put the Prusa Core One through its paces with a range of filament types and projects, and the machine held its own even on more complex prints. From office accessories to video game models and props—including the official Borderlands 4 prints available on printables.com—everything worked flawlessly and demonstrated just how versatile the Core One is.

It adapts to different filament types with ease, and the ability to send and track prints directly from the slicer makes the entire process simple and, for the most part, painless. You do need to monitor how much filament is loaded, and multi-colour printing isn’t available out of the box—though it can be added as an upgrade. Beyond that, everything just works, and works well.

There’s a lot to like about the Prusa Core One. The company has built a machine that feels ready for almost anything, though it does come at a premium. Retailing at $1199 fully assembled or $949 as a kit, it lines up competitively against feature-rich rivals such as the Bambu Lab X1 Carbon. An optional upgrade kit allows existing Prusa MK4S owners to convert their current printer for $449, offering a smart path forward for loyal users. I can’t personally attest to how easy this conversion is, but based on user threads, it appears comparable to building the Core One from the kit, with a few additional steps.

For me, the Prusa Core One’s appeal lies in its blend of reliable operation, thoughtful design and genuine openness. There’s no forced account system or cloud lock-in. Tinkerers can connect the printer to automation systems, experiment with custom firmware, or simply leave it as-is and enjoy years of fuss-free printing. Support for the MMU3 multi-material unit is also available, adding five-colour printing for those who need it. We plan to test this add-on in the future to see what flexibility it brings to the overall system.

I’ll admit it—I’m sold on the Prusa experience, and the Prusa Core One is one of the best 3D printers I’ve tested to date. It’s fair to say the Core One won’t make sense for complete beginners watching the bottom line, and there are a few missing luxuries—better camera hardware, brighter enclosure lighting, and true remote-ready print farm tools may still be on some wish lists. But for users who want speed, reliability and the confidence to adapt their printer over time, the Core One delivers a well-rounded, practical package. It’s the clearest signal yet that desktop 3D printing is maturing—and doing so without losing the spirit of creative curiosity that sparked it in the first place.

- The CORE One is a 3D printing workhorse engineered in the proven Prusa tradition. Designed with a “made to last” philosophy and made from premium materials, the CORE One offers exceptional reliability with minimal maintenance. The enclosed chamber, capable of reaching up to 55 °C, features active temperature control for high-quality printing across a wide range of materials from PLA and PETG (even with the door closed) to more demanding materials like ASA, PC, or Nylon.

- Whether you’re new to 3D printing or a seasoned expert, Prusa CORE One ticks all the boxes for a reliable all-around machine. Featuring an enclosed chamber and CoreXY design, it combines high-speed printing and maximum print quality with a large 250×220×270mm print area. And there are plenty of clever design choices, e.g., an all-steel exoskeleton frame for maximum firmness and robustness. You’ll be ready to print your first model in minutes thanks to intuitive software and one-click printing.