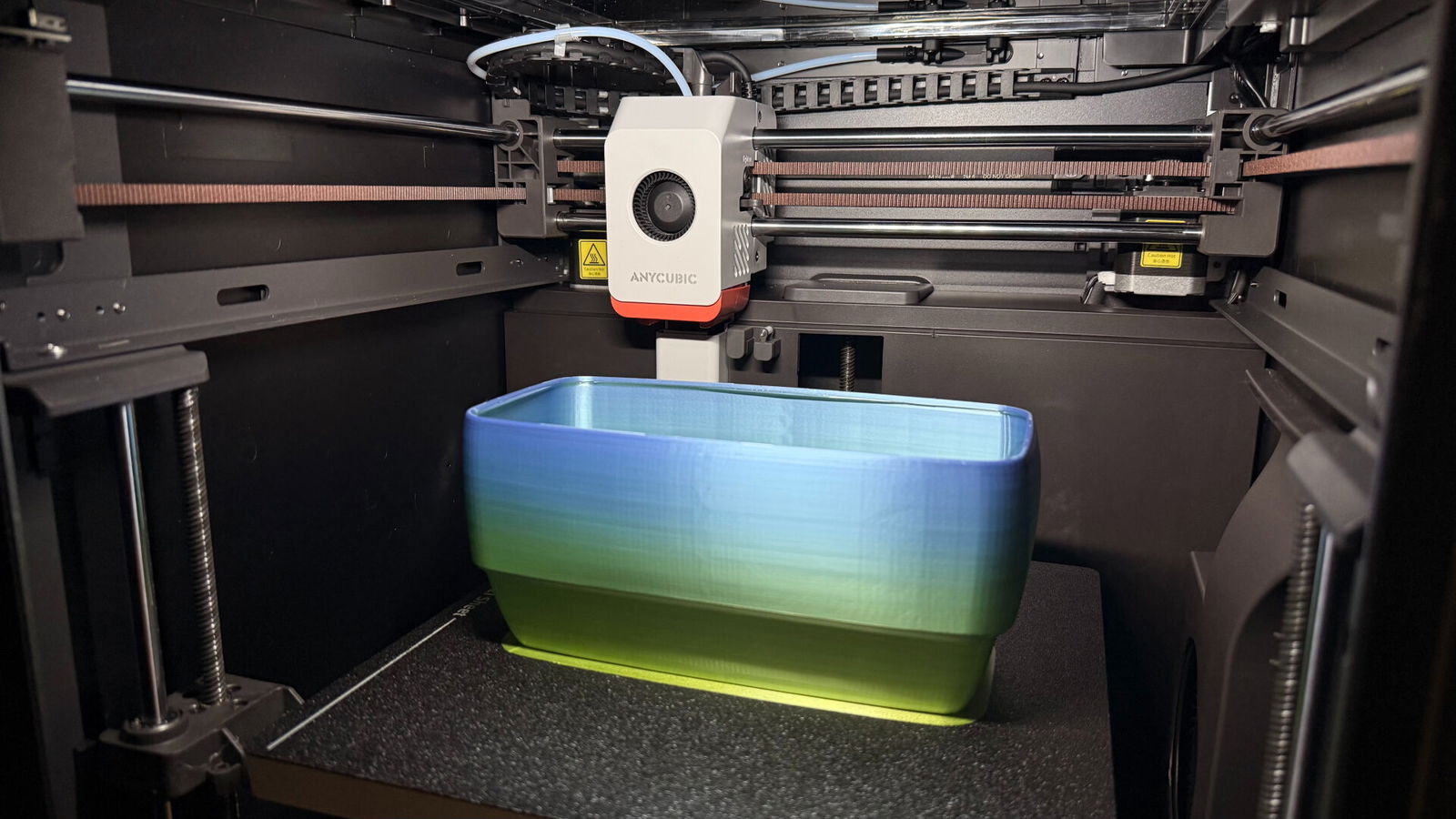

While 3D printers are becoming ever more accessible, it can still be a daunting hobby or craft to dip your toe into. Even knowing some people who have achieved great things with them, I was a little skeptical that I’d be able to do the same from the comfort of my own home. But the Anycubic Kobra S1 Combo 3D Printer changed my mind as soon as I ran my first prints. From the moment I pulled it from its (sizable) box and started setting it up, the Kobra S1 was a breeze to operate.

The Kobra S1 itself is Anycubic’s latest enclosed CoreXY, filament-based 3D printer, sold on its own or as a combo with the ACE Pro filament loader. This enables the combined machine to keep up to five colours loaded at once—four in the loader, and one on the basic filament spool on the back of the printer. (A second ACE Pro can be added as well if you have the space and inclination.)

From speaking to experienced 3D printer users, the prospect of setting one up was almost daunting, but the Anycubic Kobra S1 couldn’t have been simpler to assemble. The packing is engineered in such a way that you don’t really have to actually assemble much to get running; to explain the process in broad strokes, the internal packaging used to protect the internal components is removed with Alan keys, tubing is installed in the back, and then you’re off to the races after a brief (but very loud) self-calibration test. There’s no need to fiddle with the printhead assembly… or much else, really. It’s impressively plug-and-play for a device of this scale and purpose.

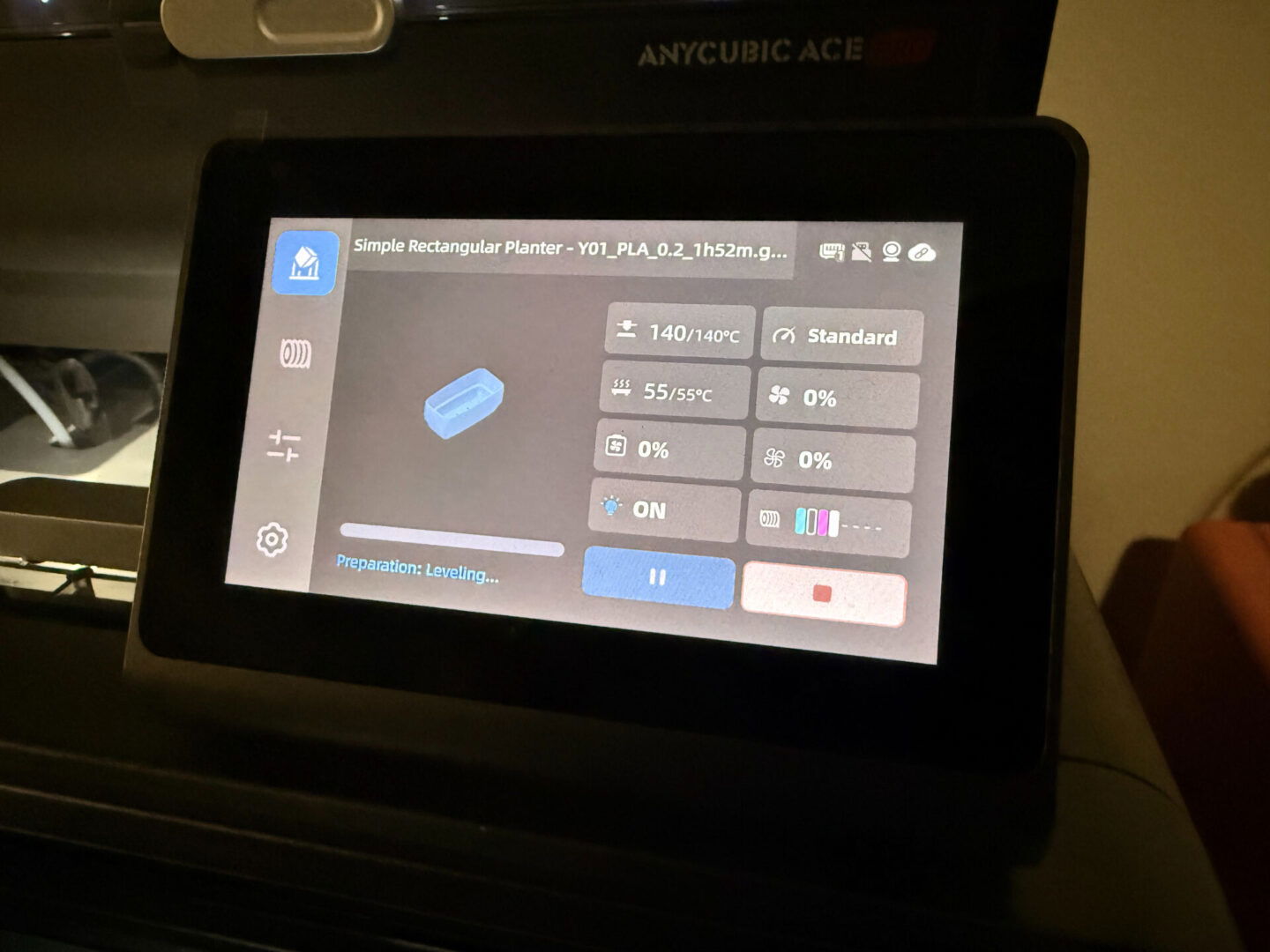

There are some basic files included on the unit, mostly for testing, but the real utility comes from the Anycubic Slicer software on PC. Thankfully, this program is almost as easy to use as the printer was to set up. It’s intuitive and automated enough that I could import downloaded STL files, manipulate them simply as needed, and send them to the printer with absolutely no experience in CAD programs. Hardware and software communicate seamlessly, and the printer’s progress can be monitored in the Slicer or on their mobile app.

“The Kobra S1 is a single-extruding 3D printer, but the ACE Pro enables it to hold and easily swap between up to four spools.”

Of all the bells and whistles included in the Kobra S1, my favourite is probably the camera built into the enclosed cabin. With either mobile or desktop software, I can easily check on the progress or outcome of the printing without having to check the printer itself or rig up a camera on the outside. It’s not picture-perfect but certainly helps ensure that the print hasn’t gone horribly wrong while your back is turned.

Not to imply that printing errors were common in my experience, however. After over 120 hours of printing time, I ran into only a handful, and most of them could be chalked up to user error or problems with the STL. The Kobra S1 handled these issues considerably well. There was one instance, during a particularly large print, where the printhead presumably hit the door, and I came back to find the assembly cover had fallen off and out of the machine entirely, leaving a pile of “spaghetti” behind. (I then ran it again, but with the door opened, and there were no issues, so I suspect a problem with the file.)

There are a couple of other features on the Kobra S1 that would help in such situations. With one extra click during the start of printing, Time Lapse recordings can be enabled, saving a sort of recording to a USB thumb drive. There’s also AI-powered “spaghetti detection,” able to assess your print in progress and alert if it detects this infamous error in 3D printing. (Wish I’d had both features on for that aforementioned glorious mistake.) Having only expected the usual statistics from a 3D printer, such as temperature monitoring, these extras really tied together an exceptional package.

Now, if the prospect of printing four different colours at once was appetizing, it should be noted: that’s not four colours simultaneously. The Kobra S1 is a single-extruding 3D printer, so it only does one filament at a time, but the ACE Pro enables it to hold and easily swap between up to four spools. This in itself is incredibly handy. Not having to change between filament rolls manually anytime you want to swap colours, while keeping the rolls stored properly, is worth the extra money.

That being said, the actual reality of printing multiple colours comes with some baggage. For example, the four-colour model included on the system prints a simple fidget toy or gizmo; for each layer of the model, the Kobra S1 would draw all of the first colour, then reset, swap colours, reheat the nozzle, and then draw all of the second colour, and so on until all the colours were done. Then it would move to the next layer and start the process all over again. This simple doodad (pictured above) took about 17 hours to print, and half of the time was likely spent resetting and reheating, not actually printing.

Don’t get me wrong, it’s still an asset to have this option. Realistically, depending on what you’re printing, a multicoloured design won’t require each colour on every line like this included test print did. Just prepare for such prints to take a very long time, even above the time estimated by the software, especially if they’re alternating between the different filaments on many layers.

“Despite a couple foibles—things that user discretion before printing can mitigate—the Kobra S1 truly exceeded my hopes and expectations.”

The other inconvenience of colour swapping? Since the Kobra S1 can use multiple filament rolls through the same hotend, it will eject little bits of material whenever it swaps over. This excess trickles out the back end of the printer, not unlike… well, poop, as the 3D printing community has dubbed these little balls of waste. I was unprepared for this byproduct, so the first time I had to move the printer after a good dozen hours of experimentation, including that 17-hour multicolour print, I unleashed a trickle of plastic rain down the back of the desk. (One of your first prints should be a “poop basket” to help keep the area tidy.)

Truth be told, I didn’t have to move the Kobra S1 unit often—which, like our editor-in-chief can sympathize after reviewing Anycubic’s latest resin printer, is a blessing; this is a chonky system. I did, however, need to do so on two occasions to clear filament jams. Luckily, this proved far simpler than it sounds. The piece where all four filament tubes feed from the ACE Pro into the Kobra S1 was easily unscrewed, and then it was simply a matter of pulling the excess strand of filament straight out and reattaching. Like the earlier incident with the printhead falling off, this “maintenance” was very simple.

Filament problems with this model were reported fairly often within Anycubic’s community during a particular firmware release during my testing for this review. I only had a couple errors, fortunately, and they have not reoccurred since that firmware was replaced.

Now, with those caveats out of the way, I can gush a little bit. Despite a couple foibles—which, again, are things that user discretion before printing can mitigate—the Kobra S1 truly exceeded my hopes and expectations.

From the moment I first saw a 3D printer running at a local convention, it’s been a field I’ve wanted to explore. I knew some tricks from talking to those who’d been doing it for a while but doubted that it was feasible for me to pursue. Yet the entire process was incredibly smooth, thanks to Anycubic’s design. I didn’t have to worry about technical issues with the printer itself, aside from a handful of minor problems—a pretty solid margin of error for 3D printing.

This frees users up to get creative with the designs they print, as well as the materials. Technically, the Kobra S1 accommodates a whole variety of material options, including the standards (PLA, PETG, TPU (95A), ABS, and ASA) and rarer, high-temperature materials (PC, PA, carbon fibre, and glass fibre). Though I only tested it with various forms of PLA, both Anycubic’s own brand and others’, it’s reassuring to know that it can work with more sophisticated materials too.

The Kobra S1 Combo isn’t just a bundle, it’s truly an all-in-one solution suitable for a wide range of 3D printing enthusiasts. Its sizable printing area (250x250x250mm) enables large projects, while I was also able to successfully print a couple miniature projects, provided the supports were designed properly; luckily the slicer software can assist with that. Resin printers may be superior for minis, and it won’t print a full-sized adult helmet for cosplay in one piece, but it’s well-suited for just about any other purpose in between.

I can heartily recommend the Kobra S1 to anyone who’s serious about investing in this space for just about any purpose. Whether you want to mass produce designs for work, make some fun projects with your kids, or bring some creative dreams to life, Anycubic’s combo offers what you need to get it done without stressing over the technical side—and that in itself is something of a miracle.

- 【Multi-Color 3D Printing Made Easy】 Anycubic Kobra S1 Combo handles 4-color printing right out of the box. For even more creativity, pair two units for stunning 8-color prints, eliminating the need for manual painting. For optimal quality, we recommend using the same type of filament throughout your print.

- 【Built-In Filament Dryer】 No separate dryer needed! Anycubic ACE PRO actively dries your filament 24/7, even during printing. This ensures peak performance, prevents printing issues, and supercharges your workflow.